Spun-Confl nonwoven machina

MACHINE SPEED:9-500 M/MIN

FILAMENT DENIER:SPUNBOND:1.5~2.5 D; MELTBLOWN: 1.6~4μm

PONDUS TEXTUS 9 ~ 70GSM

ORDO POLYPROPYLENE GRANULUM FIBRA GRANUM INCOCTUS; MFI 25-40 PRO SPUNBOND; MFI DCCC~ MDC PRO MEL TBLOWN

ACTUS TEMPUS: 6-7 MONTHS

Spunmelt machina non texta petitores fabricae:

Machina Spunmelt non texta fabricam spunmelt, fabricam spunbondam producere potest et fabricam conflatam conflare, cum priora machina extra telam et machinam viscum gremio, machina spunmelt et fabricam spunbondam producere et fabricam simul conflatam conflare potest.

Fabrica ex machina spunmelt adhiberi potest ad larvam faciem producendam, diaperam, mappam, qualitatem medicinae usus, vestis, operatio suit.etc

JIASHAN HH Nonwovens Machinery CO., Ltd est China Spun-Confl nonwoven machina Pariatur. Cum qualitate stabili et facili operationis lineae productionis non contextae, productus noster regularis includat trabem unam, trabem duplicem, SSS, SMS, SMMS, SSMMS et etc., latitudo regularis est 1600mm, 2400mm, 3200mm, 4000mm, 4200mm; Transierunt IS09001 qualitas administrationis certificationis systematis, Tota linea valde automated est. Tota linea est bene structa et facilis ad operandum. Elementa temperantiae sunt notae facundiae, magni effectus, technologiae certae. Tota linea a PLC refrenatur et cum velamento tactui operabatur. Destinatio instrumentorum principalium et auxiliariorum specialiter designari et adaptari potest secundum exigentias clientium.

-

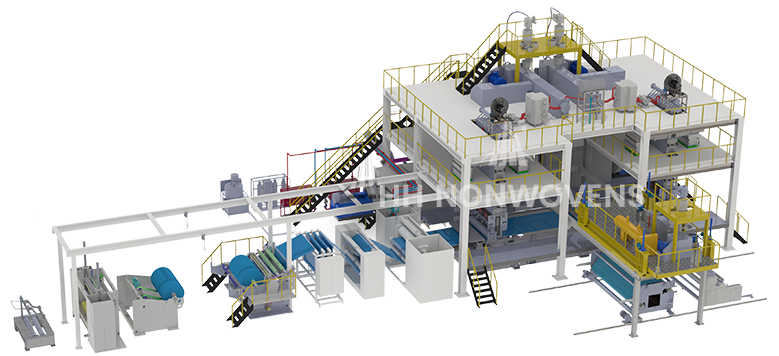

Tres trabes (SMS) Spun-Confluat nontexta machina

Facultates copia: IV SETS / mensis Portus: Shanghai Payment Terms: TT.LC, alii MACHINA EXEMPLUM: SMS (Spunbond conflandum canite Spunbond) MACHINE SPEED:9-350 M/MIN FILAMENT DENIER:SPUNBOND:1.5~2.5 D; MELTBLOWN: 1.6~4μm PONDUS TEXTUS 9 ~ 70GSM REFE...See More

-

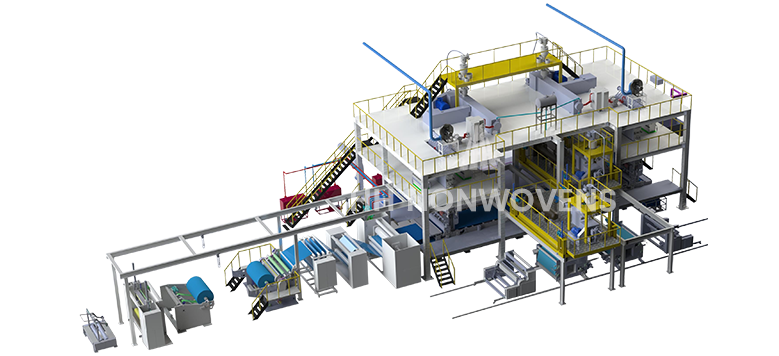

Quattuor trabem (SMMS) Spun-Confluat nontexta machina

Facultates copia: IV SETS / mensis Portus: Shanghai Payment Terms: TT.LC, alii MACHINA EXEMPLUM: SMS (Spunbond conflandum canite Spunbond) MACHINE SPEED:9-350 M/MIN FILAMENT DENIER:SPUNBOND:1.5~2.5 D; MELTBLOWN: 1.6~4μm PONDUS TEXTUS 9 ~ 70GSM REFE...See More

-

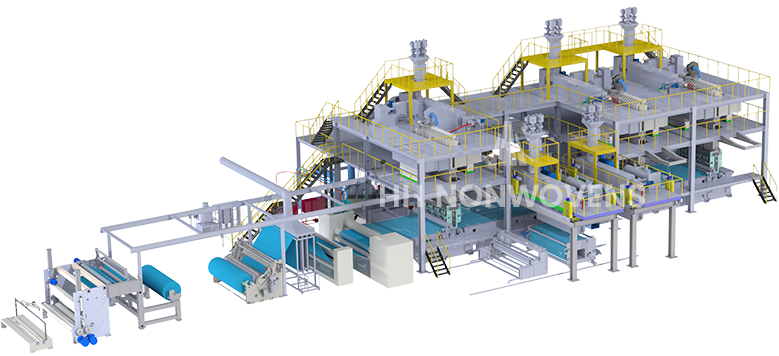

Quinque trabes (SMMSS) Spun-Conque non texta machina

Facultates copia: IV SETS / mensis Portus: Shanghai Payment Terms: TT.LC, alii MACHINA EXEMPLUM: SMMSS (Spunbond conflandum canite conflandum canite Spunbond Spunbond) MACHINE SPEED:9-550 M/MIN FILAMENT DENIER:SPUNBOND:1.5~2.5 D; MELTBLOWN: 1.6~4μm PONDUS...See More

Industria scientia

Potest autem producendum et spunbond et conflandum, canite textilia eodem tempore?

English

English